The standard square shaft piles are usually installed using compact equipment, like a skid-steer loader or an excavator, equipped with an hydraulic drive head. This makes the installation process quicker but also lessens the requirement to prepare the ground thoroughly. The operator plays a crucial part in making sure that the piles are installed plumb, using both visual cues and assistance from ground personnel.

One of the main aspects of helical pile installation is achieving the capacity of load you want to achieve. This is where the correlation between the installation tension and capacity is vital. Contemporary torque indicator, such as the Chance Digital Torque Indicator, play a pivotal role in this process by providing precise measurements and eliminating the uncertainty in hydraulic pressure estimations.

The speed of operation during installation is vital, generally being between 8 and 16 RPMs. This controlled speed ensures that the pile moves approximately 3 inches every revolution which is in line with the helical plates' pitch. If the pile does not move according to plan, adjustments such as raising downward thrust or adding larger plates to prevent'spinning out' like the threads of a screw being stripped.

Screw Piles Market Size to be Worth USD 1.56 billion by 2031, at a CAGR of 5.5 %| Transparency Market Research, Inc. GlobeNewswire

Posted by on 2024-01-03

Grand Forks begins multi-year expansion of wastewater treatment plant Grand Forks Herald

Posted by on 2023-11-06

VersaPile a versatile helical steel pile contractor in Manitoba - constructconnect.com Daily Commercial News

Posted by on 2023-10-02

DFI Announces Recipients of the 2023 Legends Awards Tunneling Business Magazine

Posted by on 2023-09-06

What Are Helical Piles Used For - Make It Right® Mike Holmes

Posted by on 2023-08-03

Volusia homeowners install piles as retention pond threatens foundations WKMG News 6 & ClickOrlando

Posted by on 2023-07-11

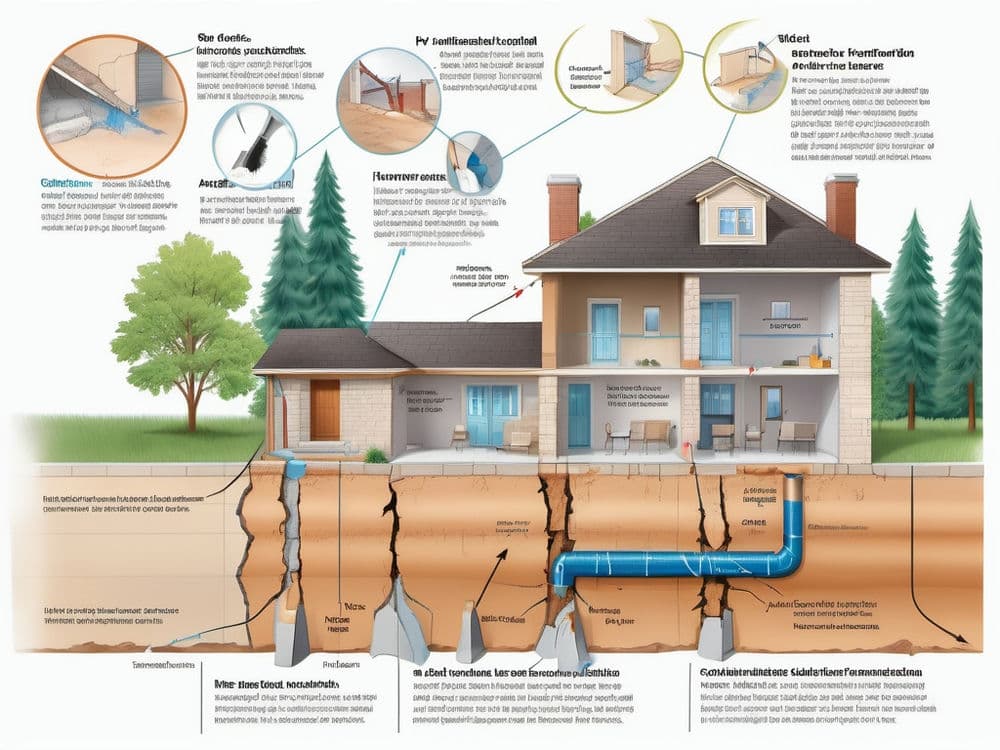

The variety that helical piles offer is yet another reason for their increasing popularity. They can be utilized in a wide range of soil kinds which include those that are challenging for traditional foundations. Their flexibility makes them an ideal choice for sites that have a problem with soils, large water tables, or limited access. Furthermore, their design can be customized to meet specific load requirements and therefore, they are suitable for a wide range of uses, from homes to industrial projects.

Helical piles, sometimes referred as screw piles, are a type of deep foundation system consisting of one central shaft with some or all of the blades that are shaped like helixes. The design permits them to be screwed into the ground, providing a secure and stable foundation for various types of structures. Originating from the 19th-century innovations by Irish engineer Alexander Mitchell, helical piles have advanced and are at the forefront of modern foundation technology.

One of the best advantages of helical piles are their speed and ease of installation.

In addition to their core advantages, helical piles have a variety of other advantageous features that further strengthen their place in modern construction. These include:

These additional advantages, when combined with their primary benefits, are what make Helical piles a highly versatile and reliable foundation choice for a range in construction tasks.

Versatility is a key attribute of the helical piles. They can be adapted to a variety of soil types and conditions, which makes them a viable option for a variety of projects, from residential buildings to industrial structures. The design of their construction can be customized to meet the specific requirements of load which makes them more suitable for different construction scenarios.

Helical piles also offer the benefit of instant load-bearing capacity. Once installed, they can support loads right away and offer a distinct advantage over traditional methods which have to wait for concrete to cure. This feature is especially useful when projects have strict deadlines or situations when time is crucial.

The sustainability aspect of helical piles should not be neglected. They are usually made from recyclable steel, and they are fully accessible, which allows for reuse in subsequent projects. This reuse, along with their reduced carbon footprint when they are installed, aligns well with the increasing focus on eco-friendly construction practices.

In conclusion the hidden advantages of the installation of helical piles such as speed, low environmental impact, versatility, immediate load capacity, and sustainability - explain their growing popularity in the construction field. As we continue to seek for more efficient, economical, and environmentally sustainable construction methods, helical piles stand out as an effective, creative solution for modern construction challenges.

Building on the foundational strengths of helical piles Their use in construction projects offers many advantages. They can be described in the following manner:

These factors highlight the many advantages of the use of Helical piles, emphasizing their role in enhancing efficiency, sustainability, and cost-effectiveness in construction.